X

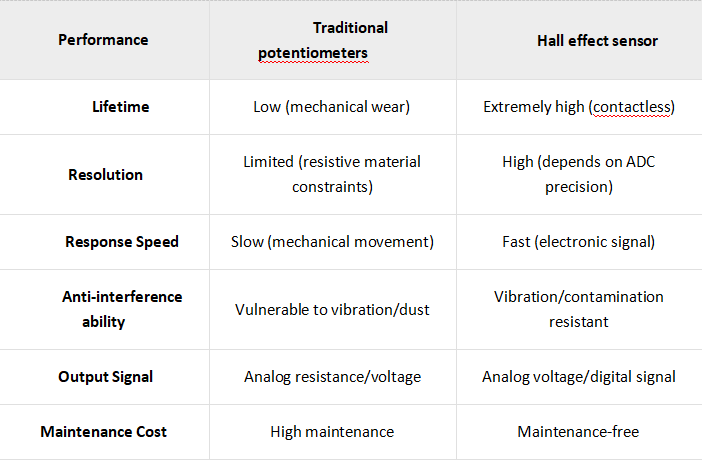

As the core sensing unit of intelligent valve positioners, position sensors undertake the critical function of providing real-time feedback on spool displacement. The performance parameters directly determine the dynamic response characteristics, positioning accuracy, and long-term operational reliability of the control system. Although traditional potentiometers (i.e., resistive displacement sensors) offer advantages such as simple structure and low cost, they exhibit the following technical bottlenecks in high-end industrial applications:

1. Mechanical Wear Issues:

Potentiometers rely on physical contact between the wiper and resistive track for signal output. The contact resistance drift caused by friction during long-term operation can expand the linear error to ±1%~5%. In extreme conditions, this may even result in intermittent signal failures, significantly raising maintenance costs.

2. Insufficient Environmental Adaptability:

In harsh environments such as chemical, power, and metallurgy, dust particles, corrosive media, and mechanical vibrations can easily cause poor wiper contact. Statistics indicate that the annual failure rate in such environments can be 3-5 times higher than that in traditional working conditions..

3. Precision Limitations:

Due to constraints in resistive material uniformity and manufacturing processes, high-precision potentiometers require complex techniques like laser trimming, leading to exponentially increasing production costs.

The Hall-effect displacement sensor is a non-contact position detection device based on the Hall effect, capable of precisely measuring linear or rotational displacement through magnetic field variations. POWERFLOW IP6000 series positioners will be fully upgraded to Hall-effect sensors, with the following core advantages:

1. Enhanced Reliability: By eliminating mechanical wear through non-contact measurement, the Mean Time Between Failures (MTBF) reaches 200,000 hours, meeting the demanding requirements for continuous operation.

2. Improved Precision: Through three-dimensional magnetic field modeling to optimize the magnetic circuit layout, combined with high-performance chips, the sensor achieves high-resolution linear displacement detection. This represents an order-of-magnitude improvement in precision compared to traditional potentiometers.

3. Reduced Maintenance Costs: It reduces the maintenance cost caused by long-term use of the potentiometer, increases the equipment running time, makes the sensor maintenance-free, and reduces the overall operating cost of the enterprise.

POWERFLOW IP6000 series of intelligent valve positioners fully adopt Hall sensors, which is not only a significant product enhancement but also a comprehensive practice of the "Reliability-First" philosophy of POWERFLOW. Adhering to this product philosophy, we will continue to strive, continuously refine and iterate our products, and provide customers with professional and consistent products and services.